Overview

The Faraday Institution’s Battery Degradation project is led by the University of Cambridge, along with eight other universities, and numerous industry partners. We have been funded for a further two years taking our funding to £22M over seven years. From 1 April Professor Louis Piper at Warwick Manufacturing Group at the University of Warwick joined the project as co-PI, sharing the Principal Investigator duties with Professor Dame Clare Grey.

Using a suite of advanced modelling and characterisation techniques, the project aims to understand the mechanisms of degradation of lithium-ion batteries containing high Ni-content NMC, cobalt-free cathodes and a range of anode chemistries from graphite, graphite/SiOx composites and anode-free.

This project is examining how environmental and internal battery stresses (such as high temperatures, charging and discharging rates) degrade electric vehicle (EV) batteries over time. Results will include the optimisation of battery materials and cells to extend battery life (and hence EV range) and reduce battery costs.

Despite the recent reduction in cost of lithium-ion batteries driven by mass manufacture, the widespread adoption of battery electrical vehicles is still hindered by cost and durability, with the lifetimes of the batteries falling below the consumer expectation for long-term applications such as transport.

Additionally, fast charging of battery electric vehicles is crucial to help assuage range anxiety and provide the operational convenience required for mass adoption of the technology. Fast charging, however, can rapidly accelerate degradation and even trigger degradation mechanisms that are not present in ‘normal’ operating conditions. A key goal for the automotive industry is to understand more fully the causes and mechanisms of degradation to enable improved control and prediction of the state-of-health of battery systems.

The goal of the project is to create accurate models for use by the automotive industry to extend lifetime and performance.

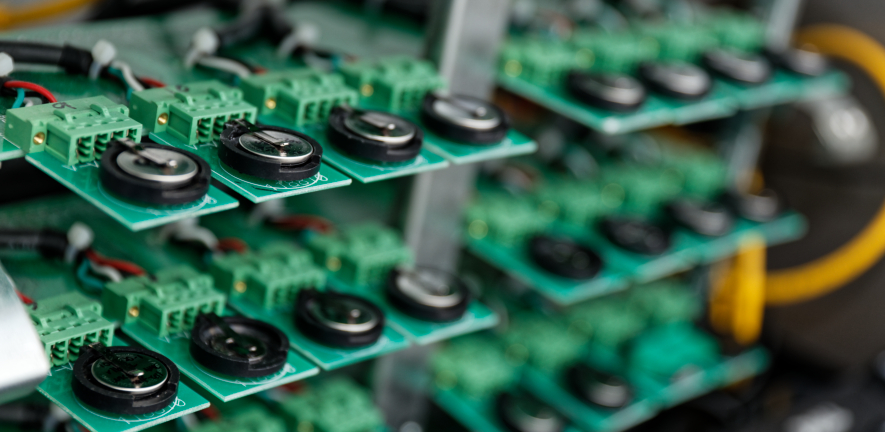

We are supported by WMG’s Battery Scale Up facility. We aim to optimize various permutations of different battery chemistries by controlling the manufacturing processes and innovating electrode and liquid electrolyte components.

Key Innovations:

- High energy density cells: Utilizing LiNiO2 with Si-doped graphite and NMC811 with SiOx-graphite.

- Safer, low-cost cells: Employing LMFP with graphite.

- Post Li-ion cells: Developing NMC811 with anode-less configurations for in-situ Li plating/stripping.

Advantages of Our Approach:

- Collaboration with FutureCat: Leveraging their LNO for scale-up activities.

- Advanced measurement techniques: Using A7 single layer formats for operando X-ray measurements.

- Knowledge transfer: Sharing insights with the wider Faraday Institution community.

Our dedicated single layer cell builds at WMG’s BSU facility will drive these innovations, providing significant advantages over previous cell designs and supporting the electrolyte screening and SEI characterization efforts of the Degradation project.